Products

Contact Us

Tel: +86-510-81818636

Fax: +86-510-81818633

E-mail: mould@sfxsteel.com

Address:

Location: HomeProducts

|

Sweden Scana Iron and Steel Group The leader of free forging |

|

|

Sweden Scana is one of the longest iron and steel groups in the world. In 1656, Berg iron, the subsidiary of Scana, who was founded in 1652, built the world's first forging machine. Scana is the first one of the world to apply steam power in forging production enterprises, which makes it to become the leader of European forging technology in 17th and 18th century.

|

|

|

In 1994, Scana purchased Bufuge, who has a longest history of forging and heat treatment developing in Europe, which enhanced advantages of Scana in melting, forging and heat treatment developing. With a long history of more than 360 years, Scana keeps focusing on iron and steel forging, accumulating knowledge and developing new technology, which makes it to be the recognized leader of free forging. |

| Scana has its own steel mills and modernized forging workshop, and is equipped with a full range of heat treatment equipment and mechanical processing shop. |

|

|

Scana can supply forged rods with a maximum amount of 54 tons of forgings and forged rods with a maximum length of 24 meters, main customers include oil and natural gas industry, shipbuilding industry, energy industry, heavy machinery manufacturers. |

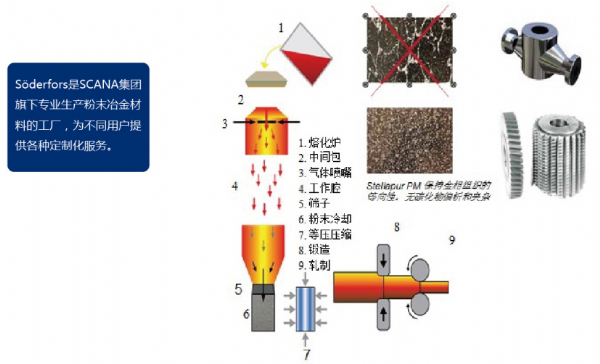

| Powder metallurgy——to create unparalleled material properties |

| The technology of powder metallurgy is the science and technology of tomorrow. We have sufficient professional competence of applying powder metallurgy technology to meet the increasingly stringent requirements of customers on the reliability and performance of cutting and cold work tools. |

|

| Stellapur——Pure steel with long life |

|

Stellar is a series of steel products of Scana, which means more pure, more precise chemical constituents, better wear resistance, better strength and toughness. For the growing application requirements, Stellapur is rotating at high speed, which makes it to be the unique choice in the aspects of lightweight and energy-efficient. Stellapur——Ultra-pure melting technology With more than 360 years of experience in steel production, Scana developed SuperClean, the ultra-pure melting technology. Of which, the core is to add special purification process during the smelting process, and remove phosphorus and sulphur and other impurities repeatedly, so that the purity can meet even higher than the standards of ESR. In 2005, on the basis of super clean technology, Scana begins to apply more advanced (VIP) technology, by which the grade of materials of die steel can reach even above the level of PESR, and the fatigue resistance of materials can be improved. VIP melting technology

VIP melting technology, one of the core technologies of Scana, is the strength of Isotropic melting on the basis of ultra-pure smelting and three-dimensional forging. The microscopic metallurgical and toughness of materials can be greatly improved by applying this technology to improve the shape of inclusions and reduce the size of inclusions. More than 360 years of experience and technology of forging Scana spent all efforts on developing, summarizing and accumulating forging technology. With more than 360 years of focusing on the forging of different grades of products, Scana has achieved the highest standards of forging in the world, and got more than 100 senior engineers of forging with experience over 30 years. Multi-Top——Multi-stage heat treatment process The most important core technology of Scana the multi-stage heat treatment process applied for heavy forgings. For the production of high-end materials, heat-treatment and forging process can not only ensure the final quality of its products, even improve flaws during the melting process. With the unique technology, developed for heavy forgings by applying multi-stage heat treatment process, and excellent forging technology, Scana sets higher levels of quality standards for all standard grades of tool steel products.

The inspection level objectives of all standard grades of forging products of Scana have achieved SEP1921Ee. For our customers, they only need to get an ultrasonic flaw detector, so they can quickly distinguish high standard of mold steel products of Scana. The third-generation of high-speed steel powder

Scana is one of the few providers in the world to provide the third generation of high-speed steel powder. The predecessor of Sodermalm, the subsidiary of Scana, is the birthplace of the third generation of high-speed steel powder production lines. So in terms of quality, product, purity or density of isostatic pressed billets, the high speed steel powder products provided by Scana are consistent with the top-end high-speed steel powder in the market. Quality controlling Products produced by Scana can meet the needs of the most demanding customers. For example, offshore engineering construction, large transmission equipment, ships admired parts, defense equipment, wind and water-engine equipment. The selection of raw material, and processes of smelting, forging, heat treatment, machining and so on are finished independently by Scana, all the production processes are controlled by strict quality inspection and control system. Scana quality system (excerpt)

|

|